Industrial Design Archives Project

Industrial Design Archives Project

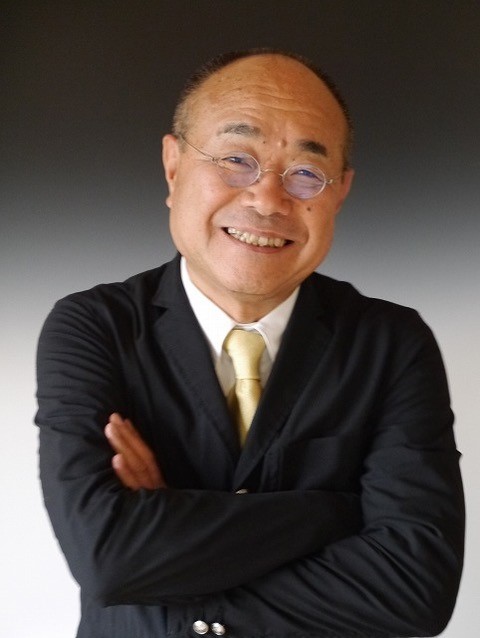

Designer Testimony 08

It all began with the T-shape

Ichikawa Kuniharu

Born in Osaka in 1949, Ichikawa Kuniharu joined Matsushita Electric Works Co., Ltd. (currently Panasonic Corporation) in 1967 after graduating from the industrial design department of Osaka Prefectural Nishinoda Technical High School (currently Nishinoda Technology Senior High School) in 1966. He has worked in advertising planning, housing equipment, and home appliance product design, and has served as product planning department head and General Manager of the Lighting Design Group, among other positions. He participated in product development and created hit products in a wide range of fields including electric shavers, massage chairs, hair irons, and tempura oil cleaners. After reaching mandatory retirement and leaving Panasonic in 2009, he established Kuniharu Ichikawa Design Office. In addition to part-time lecturing at universities and at a human resources development institute, he provides services as a product development and design consultant.

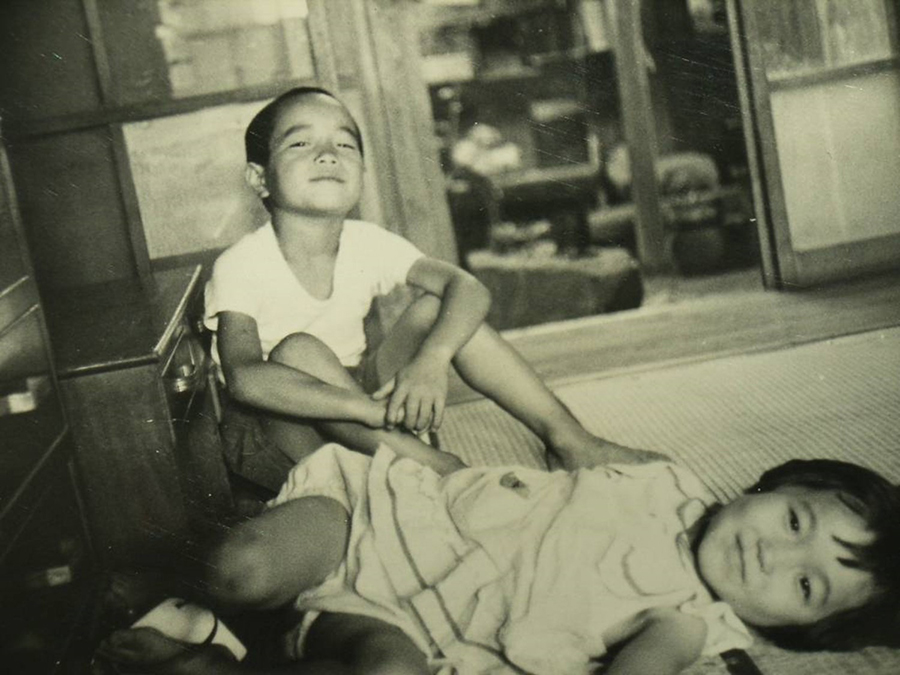

Born in Osaka

I was born and raised near Tenmabashi in Osaka. My mother and father worked at home, cutting and sewing kimono fabric in a sort of cottage industry. We had a tiny house with a tiny garden, and since it was just after the war, we still used firewood for cooking rice. I remember playing near the Okawa River—it was a good place for sword fights.

For high school I studied in the industrial design department of Nishinoda Technical High. Before the war, it was a woodworking department, but after the war, it changed to industrial design. While I was there, a lot of girls entered the school all at once, and more than half of the design students were girls. All of the girls were smart. Later I heard from a teacher that one of them had even received a perfect score on her high school entrance exam. I was no good at studying, so I spent all my time practicing judo in my after-school club!

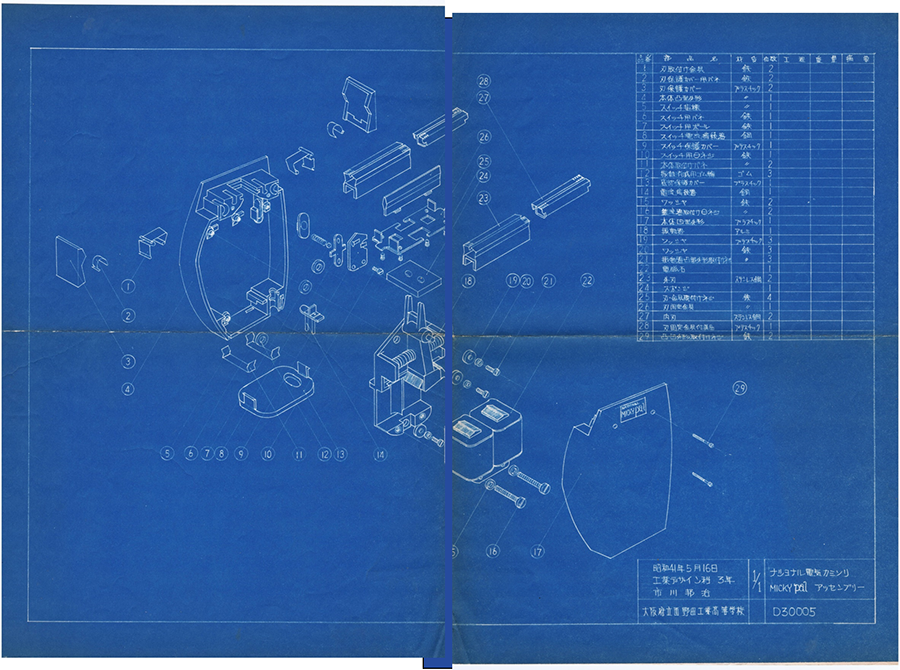

When I got my first high school (design) assignment, during my second year at the school, I happened to choose an electric shaver . So, out of the blue I called Matsushita Electric Works and asked them to “tell me about electric shavers.” You can do that kind of thing in Osaka! He’s since passed away, but I met someone called Mr. Ono, who told me all sorts of stuff. I went home with a broken electric shaver that he gave me. I was busy with job hunting from the beginning of my third year, but I think the recruitment test for Matsushita Electric Works was in May or June. I didn’t have any special recommendation from the school, and there were no Nishinoda Technical alumni at the company who could pull strings, so it was all going to be up to my performance on the spot. When I raised my hand at school and said, “I want to take the test!” the teacher said, “If that’s the case, go ahead and take it… I’ll write that you got the best grades.” The test guidelines said there was no need to bring any samples of work, but I thought I would fail if I didn’t, so I made various things like renderings and isometric drawings and took them with me. I also took a drawing that I made of the electric shaver that I received from Mr. Ono, which I had taken apart. I wanted the HR people who might be inclined to say “No” to take another look at me. Thankfully, although my English and math scores were close to zero, for some reason I was hired.

Micky Pal assembly diagram, created for Matsushita Electric Works recruitment test

Becoming a Matsushita Electric Works employee

After joining the company, I lived in the company’s singles dormitory. Morning, noon and night, I ate in the employee cafeteria. Then I did my factory training, sales training, and assigned factory training, and I was assigned to the Lighting Division. I joined the company in the first place because I wanted to handle product design, but there was an urgent need for people to help with catalog production, so I spent three years making catalogs and flyers in the Planning Section of the Planning Department. To my surprise, those three years were extremely meaningful.

The Planning Section of the Planning Department was a department where we had to do any and every type of work. In those days, the business day started at 8 o’clock, so I would get to the office at 7 o’clock to clean it, update sales graphs for the managing directors’ office, and design, print, and ship catalogs. When there was an exhibition, we would pack up and ship the products to be exhibited. We did the packing outside, so I got a tan as I worked. Also, we handwrote final clean versions of the presentation posters that we put up for the department directors to make their announcements at company-wide meetings– –something like what you would call presentation boards today. Sometimes I would be working overtime past midnight and I would get a phone call saying something like, “We’re running late with setting up the exhibition, come help us right away!” I was also present at product photo shoots, so I came to know how the lighting equipment fit in its boxes. That meant I could unpack the lighting equipment efficiently and set it up at an exhibition site. After that, I was put in charge of setup for the next exhibition onwards. I was in charge of setup for a long time. We would set up, explain, clear out, and go all around the country– –we handled everything, from A to Z. This experience in the planning section was useful later on.

But I still wanted to do industrial design, and I reminded both the section chief and the department head whenever I had the chance. But they still didn’t shift me over to a design role. So I entered all kinds of outside competitions, thinking that if my name would just come up a bit they might transfer me. But that didn’t work because all I was getting was honorable mention in the “such-and-such bicycle contest” or the “such-and-such miscellaneous goods contest.”Then one time when we were doing the “1.1.2 campaign,” which meant that each employee had a one-on-one interview with their boss twice a year, I demanded to know, “When are you going to change my assignment!?” Then the director also got angry and said, “I take such good care of you and all you do is complain! If that’s how you feel, go ahead and quit!” And I said something like, “Well then, I will quit!”

In spite of that, the department head worked behind the scenes to arrange my transfer to the market development department, where I was assigned to product design. The fact is, I had received an offer from another company that I came to know through a design contest, but staying with Matsushita Electric Works and not quitting turned out to be a very good decision. I started designing like crazy. I was in Kadoma from August until February of the following year, and a bed that I designed around that time was selected for the 19th Mainichi Industrial Design Award. After that, I moved to Hikone and started working on electric shavers.

Make something, give it a try!—That’s the only way.

Of course, the people who were there before me had already made shaver designs, but they told me, “You make some, too,” so I thought, “OK, I will.” Competing with them, I made lots of models from industrial clay. When telling the official story, I often say I made a hundred, but in reality it was probably about fifty! But the section chief looked at one of the models I’d made and said, “This is it!” As a result, we sold 1.09 million units. Named the Spinnet ES620, it’s the best-selling shaver in history.

I was 22 or 23 years old, and I didn’t know anything; I just made a lot of whatever I could think of. I worked frantically, and made a whole load of models. I’m not exaggerating. The more-experienced employees around me would make comments like, “I like this one,” or “That one looks better to me.” But I’d not been there long enough to understand what was going on, so I just focused on making the models. However, the section chief who eventually selected this one took notice of various points. It was easy to hold. The blade looks big, which makes the shaver look powerful. What’s more, since there’s nothing that’s over-designed, it should be possible to manufacture it without the need for any complicated processes whatsoever. And it has a standard motor.

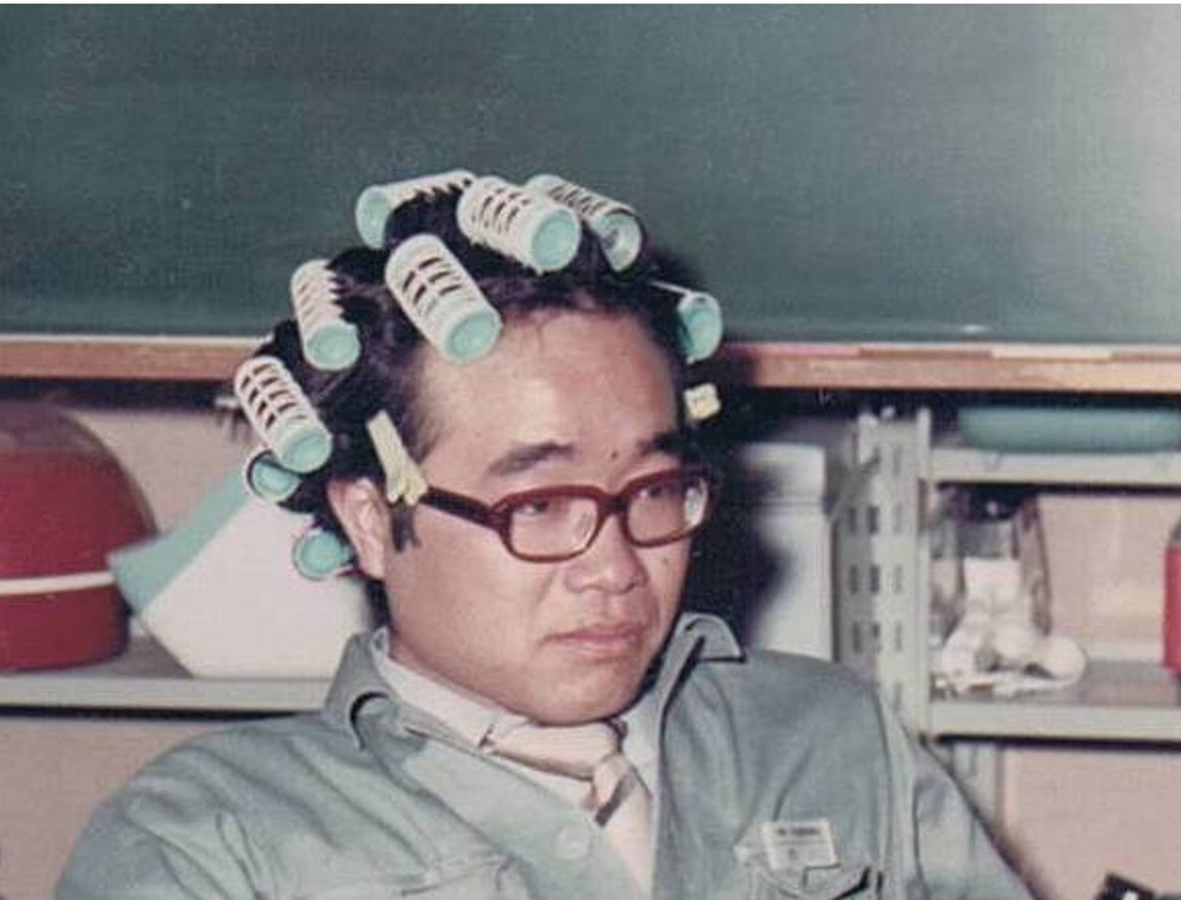

At the Hikone factory they were also developing hot curlers. The customers were usually women, but when I went there, it was all men doing the development. They were saying things like, “It’s too hot” or “It’s too heavy” even though not one of them had ever rolled their hair. Fortunately, in those days, I had hair! Playing fast and loose with company rules, I grew my hair until it just about reached my shoulders. I was able to roll twenty curlers in my own hair, so I saw that as an opportunity. I went to a meeting with curlers in my hair. No kidding, I really did. It made me dizzy and dazed. Women put up with the discomfort and do it anyway. "That’s what we’ve been trying to tell you, but you wouldn’t listen," they were saying. That’s how I got the managing director to remember my name, but for some reason he remembered it as Kurokawa!

Spinnet ES620 (1974)

The world’s first electric shaver with rotary blades made of stainless blade steel

It was manufactured from 1974 to 1978, with about 1.09 million units sold.

the shape of safety razors

One of the products included in our 50-year history of Panasonic electric shavers was the “Big Blade” (CompuShave ES840), which was an attempt at resurrecting the unappreciated reciprocating blade. It did not sell well, and an issue emerged concerning intellectual property related to the design, so the managing director who had overall responsibility for development decided to introduce a completely original product to go head to head against competing products overseas. At first, I wasn’t part of the project.

Everyone brought the design that they thought was “it” to the managing director, but I heard that he rejected about 100 designs by tossing them back across his desk. I expect that that “100” is probably an exaggeration. As far as I could tell by watching from the sidelines, they all looked like Braun’s (Note 1) designs, which gave the manager in charge of design a major headache. He came to me and asked if I had any better ideas. The managing director said, “For example, there are safety razors, too,” and my mind simply took that at face value, feeling that it would be good idea to design something like a safety razor.” I drew a picture and handed it to him, and he said, “Work on it on Saturday and Sunday.” So I prepared documents with silly arguments like this: “Braun shavers have a flat shape, so they’re held like this. Philips (Note 2) shavers have this kind of shape, so they’re operated like this. National shavers, you can really grip!” The managing director was pleased with the concept, and said it had the potential to become a world-beating product. To be honest, it all started with the managing director himself mentioning the safety razor.

Our competitors’ shavers had been dominant for so long that their shapes had taken hold in people’s minds. If I had been trying really hard to find a solution, like my colleagues were, I would also have ended up seeing those competing products as being "the shape of a shaver,” and only produce designs that didn’t diverge from that shape. In contrast, people (like me) who hadn’t been following the track so closely weren’t unnecessarily invested in specific paths. That made it easier to say “Let’s give this a try” or to ask “Why?” A similar thing happened when I once went to (Matsushita) Electric Industrial to sell them LED lighting for their refrigerators. They all came over and gathered around me and made fun of me, saying the price was too high. At that time, I noticed that their refrigerators’ vegetable drawers could only be pulled out halfway, and when I asked “Why?” they said that was how refrigerator vegetable drawers are. In the old days, the compressor was in back of the vegetable bin, so it was tiny. But when the compressor moved higher, the bottom of the refrigerator became roomier. So the vegetable drawer also grew, but because of the force of habit, they didn’t think it was necessary to open it all the way. But desk drawers and kitchen drawers open all the way, don’t they? When I said, “open all the way,” they all looked like a light bulb had turned on. Within less than a year, Panasonic refrigerators were being marketed as opening all the way!.

Note 1: Braun GmbH is a consumer appliance manufacturer based in Kronberg, near Frankfurt, Germany. It is currently owned by Procter & Gamble.

Note 2: Philips is an electronics manufacturer founded in Eindhoven, the Netherlands.

CompuShave ES840 (1975)

The CompuShave, nicknamed “Dekaba” (Big Blade) was manufactured in 1975. It was aimed at matching international products in terms of power and close shaving performance, but it did not sell well because consumers found it too bulky and heavy.

Super Razor ES820, 1977

The revolutionary T-shaped Super Razor

A company where the first to suggest something gets the job

When I was about twenty-eight years old, I was in another meeting about something-or-other, and said, “It would be good to coordinate the colors that we use throughout the company, wouldn’t it?” The response was: “You suggested it, so you can have the job! You get to chair the committee.” The designation stuck and I ended up actually doing what I had suggested. I was able to collect colors from the entire company. I suppose I got more than 20,000 colors–from housing equipment, from lighting, wiring devices, home appliances, everywhere. By coordinating these colors, we unified the colors of various products. For example, we unified the colors used for white by identifying three shades and saying, “Use one of these: A, B, or C.” That way, even products from different departments would match, and by using the same paint, we even cut costs. It also simplified operations.

Matsushita Electric Works is a great company for giving the job to the person who had the idea. That’s what makes it interesting and inspiring. That’s the big benefit of working for a company where the first one to speak out gets to follow through with the idea.

Competition and study

In order to become a manager at Matsushita Electric Works, you have to pass a management qualification exam, and the training lasts for almost a full year. There is a paper test covering labor administration, accounting, QC (quality control), and safety. I had to take notes and memorize the material, otherwise I’d never know it. Because I’m part of the baby boom generation, the competition was fierce. But that motivated me to take the initiative to study on my own, so I considered the competition necessary.

There was this sales manager who was my senior, and I respect him a lot. He had a notebook where he would write, in little teeny letters, which stores he visited and when, what gift he took and what he received in return, what they talked about. He wrote down every single thing. As sales manager, he made the rounds of thousands of National appliance shops, so he couldn’t go to each shop even once a year. At best he could go once every few years. So it’s been two years or three years since he was last there, but he starts out by saying, “That overnight-dried Pacific saury that you gave me last time was delicious.” When he says “last time,” he’s talking about two years ago! I was amazed, and thought that I really should imitate him. But, I haven’t had much success with that.

High school students, middle-aged women, ideas

When I was 33, the general manager of the business division gave me a 20 million yen budget and said he wanted me to do design planning. Basically, he wanted me to tweak products by changing colors and things like that, and find something that sells. What came out of that was the Peppermint series. We took products that had 24-year-olds as the main target and re-jigged them to target high school students. We wrote copy tailored to high school students, changed product colors, and got Nakase Asako, who illustrated a serial novel in the teen magazine Olive, to draw a character. Just changing the color of seven items and adding that character transformed the series, pushing sales up to 200 million yen.

Back then we were making water purifiers using activated charcoal. I was wondering if there wasn’t something new we could do, so I was chanting, “Make something dirty clean, make something dirty clean” while I was at a pub, drinking and eating with my partner on the project. After calling out “Tempura, please!” to place my order, I had a flash of inspiration while looking at the pot that the chef was using to fry the tempura. I said, “That’s it!” I got some of the oil from the chef and filtered it through activated charcoal from a water purifier. Lo and behold, it came out clean! My partner took the oil to Takeda Pharmaceutical and asked them to check it out, and the results showed that it was restored “like new.”

When we put out products, we did group interviews. I had a bunch of fashionable housewives come, and when I asked their opinions, they all said “No thanks.” They told us, “Oil isn’t something you use over and over.” Then when I was straightening up the venue, the cleaning lady came in and asked, “What’s this?” I gave a brief explanation and she was full of praise, saying, “Wow, this is great!” Aha! I’d been asking the wrong people! Let’s ask ordinary middle-aged women instead. Given that target market, we aired our commercials during “Mito Komon” (a televised historical drama) and suddenly we had 500 million yen in sales.

That’s how ideas come. If you keep thinking about something every day, you tend to get flashes like these at the oddest moments. They rarely come to people who don’t think about things.

The Peppermint product series

Ichikawa’s words are so effective and penetrating partly because of the quips and friendly banter of his Osaka dialect, but above all, because what says is straightforward and simple. He asks straight questions like “Why?” When he doesn’t know something, he says he doesn’t know. He explains in plain, unadorned words. He is not ashamed when he doesn’t know something, and doesn’t consider studying to be bad form. Ditto for pondering and experimenting. Within his narrative we can find many tips for making life more enjoyable. And we notice that what enables him to talk so smoothly and freely is none other than his years of steady and dogged effort.

Interviewer/editor: Keiko Ueki, Nakanoshima Museum of Art Osaka Planning Office

* Titles omitted in profiles, annotations, and supplementary explanations set in parentheses in interview articles

* This interview was conducted in 2019.

This Designer Testimony series presents digests on specific themes from the oral histories being recorded for the Industrial Design Archives Project (IDAP). IDAP plans to publish its oral histories in detail in reports and other formats.